Thermal Imaging

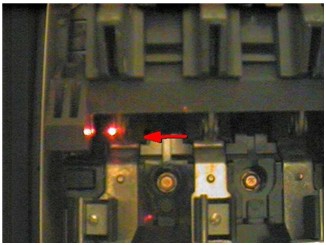

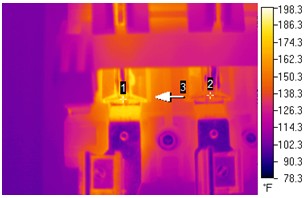

With increasing demands for cost reduction to remain competitive, many companies are expanding maintenance programs to include predictive and proactive technologies. One such technology is Infrared Thermography (Thermal Imaging). Used as a condition monitoring technique, thermal imaging enables users to identify potential areas of equipment failure and limit downtime. Van Ert Electric has the equipment and certified personnel to perform regular inspections that include scanning systems associated with critical assets - those whose failure would threaten people, property, or product. That way, you’ll have baseline images for comparison, which will help you determine whether or not a hot spot is unusual and requires repair as well as verify that repairs are successful. Our customers have realized a significant reduction in issues revealed by our Thermal Imaging Process. We can also scan roofs, steam traps, valves, gear boxes, drive couplings, drive shaft universals, belts, PLC cabinets, DCS cabinets, and motors.

For more information on thermal imaging, click here to contact a representative from one of our offices.

Benefits

- Improved safety

- Reduce unscheduled downtime

- Well planned schedule downtime

- Quality control

- Reduced spare parts inventory

- Energy savings

- Regulatory compliance

- Trained & qualified electricians

- Competetive rates

- Utilize local labor

- Coordinate & procure parts

System Partners

| Aspirus | New Page - Biron |

| Ameriprise | New Page - Stevens Point |

| Auto & Home Insurance | New Page - Wisconsin Rapids |

| Corenso | Neenah Papers |

| Hydrite Chemical Co. | Roundy's Foods |

| Kraft Foods, Inc. | US Bank |

| Land O Lakes, Inc. | Weyerhaeuser |

| Milprint - Oshkosh North | Waukesha Manufacturing |